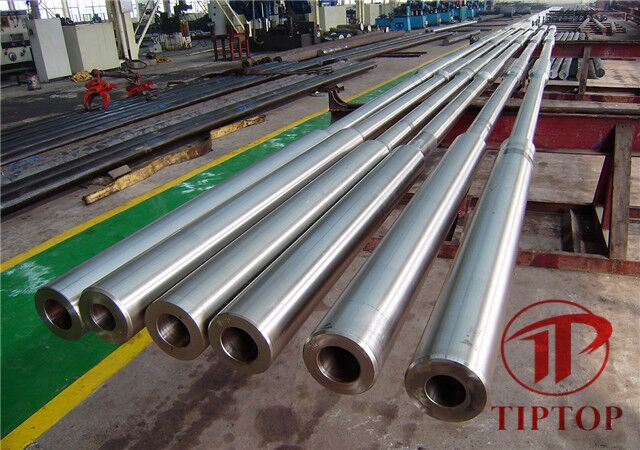

Non-Magnetic Drill Collar

Drill Collar is shorted for DC, located at the bottom of the drill string, which is a major part of the Bottom Hole Assembly (BHA).Its main characteristics are large wall thickness (generally 38~53mm, equivalent to 4~6 times of the wall thickness of the drill pipe), with large gravity and stiffness.

In order to facilitate the up and down work, the lift and slip slots can be machined on the outer surface of the internal thread of the drill collar.

Since all magnetic measuring instruments respond to the geomagnetic field of the borehole when measuring the direction of the borehole, the measuring instruments must be in a non-magnetic environment. However, in the process of drilling, the drilling tool often has magnetic field, which affects the magnetic measuring instrument and fails to obtain the correct borehole trajectory measurement information data.The non-magnetic drill collar can be used to implement a non-magnetic environment and has the characteristics of drill collars in drilling.

As you drill in areas closer to the earth's magnetic poles, it is essential to use a non-magnetic drill collar. Our non-mag drill collars offer strength and hardness while neutralizing magnetic inference. Compatible with standard drill string tools and stabilizers, our non-magnetic drill collars are manufactured to API Spec 7-1.

Please specify when ordering

●Drill collar OD and ID;

●Overall length;

●Connections required (size and type);

●Type: Slick Drill Collar, Spiral Drill Collar or Non-Magnetic Drill Collar

●Stress relief groove

●Slip and/or Elevator Recess

●Hard banding