API 16A Ram BOP for Wellhead Ram Blowout Preventer

The ram blowout preventer is one of the key elements in the well control system,which is strictly manufactured as per API Spec 16A, It is mainly used to control the well head pressure during such operations as drilling, servicing and oil testing to prevent any blow out hazard effectively and ensure safe operations. Specifically, it can be used for the following operations:

* When there is a pipe string a well, the circular space between the casing and the drill pipe could be sealed with matched pipe rams.

*When there isn’t a pipe string in a well, the wellhead could be shut off completely with blind rams.

*After the well has been sealed, such special operations as mud circulation, choking, killing and well washing can be performed through choke and kill manifold connected to spool and side outlet of BOP.

*When used together with the pipe manifold for choking and killing, it can control the well pressure effectively and achieve near-balance well killing operations.

Our bore sizes of BOP stacks from 65mm(2 9/16”) to 762mm(30”);Pressure ranging from 3.5Mpa(500PSI) to 140MPA (20000PSI)Check below:

* Bore size: 7-1/16", 9", 11", 13-5/8",16 3/4”

* Rated Working pressure: 3000Psi, 5000Psi, 10000Psi, 15000Psi. 20000Psi

* Body Styles: Single ram, double ram, triple ram

* End type: API flanged, studded and other types are available.

Our BOPs can be used to replace Shaffer ram BOP, Cameron ram BOP, or Hydril ram BOP.

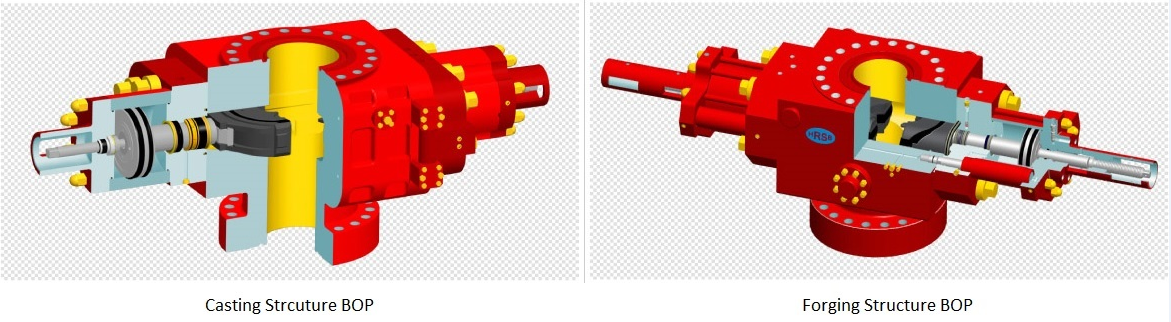

Casting structure Ram BOP

The main pressure-containing parts, such as body, bonnet, etc. use high-strength and high-toughness alloy steel material. All of the parts are shape casting and followed by proper heat treatment.

The bonnet is connected to the body by hinge which can be opened manually to replace the ram assembly. There are several slots at the ram chamber bottom of the body which can remove the mud and sand automatically during rams opening and closing, reduce the ram movement friction and also improve the ram self-sealing.

The special designed floating ram sealing structure can reducer the resistance during the ram opening and closing, extend the ram duration time by reducing the packer wear, prevent rust between the body and ram, and can be dismantled easily.

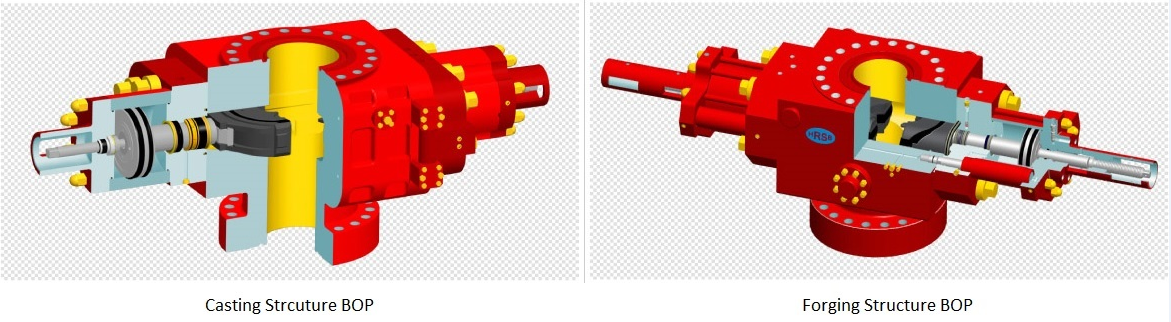

Forging Structure Ram BOP

The material of main pressure-containing parts, such as body, bonnet, etc, are high-strength and high-toughness alloy steel, which is possessed and smelted under strict control to remove harmful compositions and non-metallic impurities through secondary refining and proper heat treatment, to ensure the quality of the BOP.

The ram chamber of the body is oval shaped in order to reduce the stress connection.

The opening and closing of the bonnets and ram are operated through the BOP hydraulic control unit; the bonnet opening and ram closing can be the same operation, while the bonnet closing and ram opening also can be operated at the same time.

The ram assembly design is also oval shaped, same as the body ram chamber.