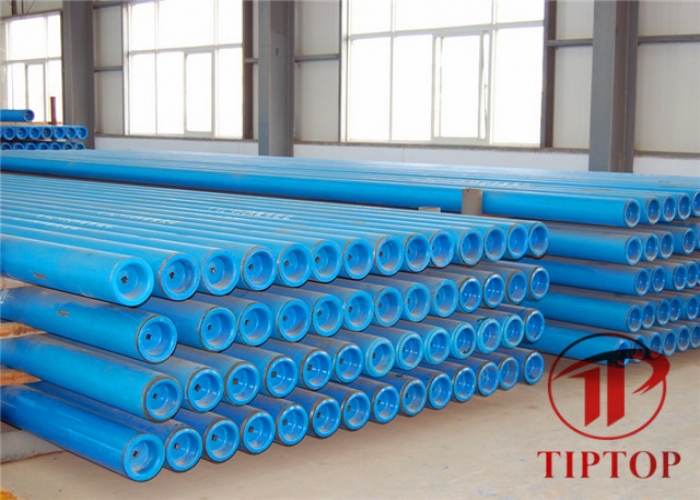

API 5LD, DNV OS F101 Subsea CRA Clad/Lined Steel Pipes

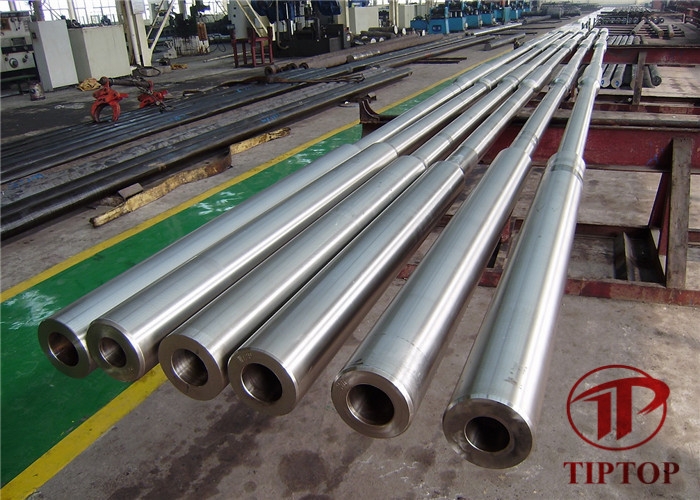

Bimetal Composite Steel Pipe is a new type of composite pipe made of carbon steel pipe lined with a layer of corrosion-resistant alloy pipe. The product uses carbon steel pipe as the base material, the outer base pipe, which gives full play to the excellent mechanical properties and low price characteristics of carbon steel pipe, that is, the carbon steel matrix ensures the overall strength of the pipe and various mechanical indicators; it uses corrosion-resistant alloy materials as the lining anticorrosion layer, giving full play to the excellent corrosion resistance of the corrosion-resistant alloy, that is, the corrosion resistance of the pipeline is ensured by the corrosion-resistant alloy lining, so as to achieve the best combination of reliability and economy of the CRA Cladded Pipe.

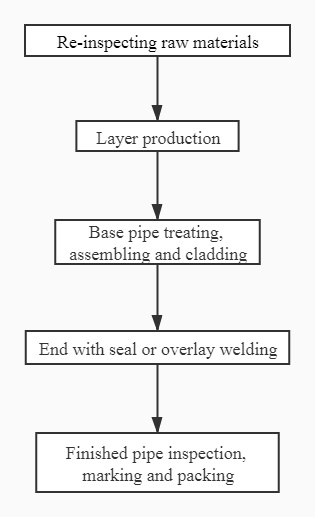

Based on the different composite methods, CRA Lined Pipes can be divided into Mechanical Lined Pipes and Overlay Welding Clad Pipes. Mechanical Lined Pipes can use two different composite technologies: the hydraulic expansion and the digital underwater deflagrating technology. Main steps are base pipe preparation including heat drying as well as sand blast and assembling base pipe and layer making assemble is under the clear condition. The manufacturing process complies with API 5LD, DNV OS F101 and Project Specifications. The base pipe can be selected from carbon steel pipes with different diameters and wall thicknesses according to the flow and pressure requirements of the transported medium. The material can be X42-X100, or J55, N80, P110, which comply with API SPEC 5L and API SPEC 5CT standards respectively. Different corrosion-resistant alloys can be utilized according to the chemical composition of the transported medium for lined pipe. It can be austenitic stainless steel 304/316L, Alloy 625/825, 22Cr/25Cr and other new high corrosion resistant alloy materials. And TIPTOP highly reliable layer products are certified with API Spec 5LC. Overlay Welding Clad Pipe adopts high-efficiency TIG welding method.

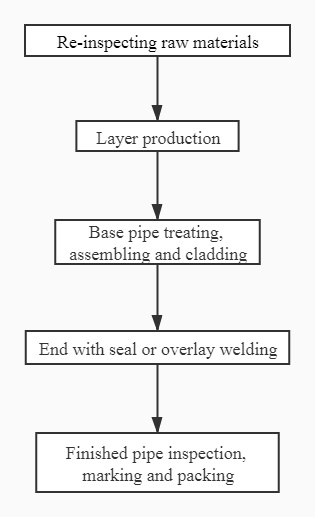

Manufacture Process

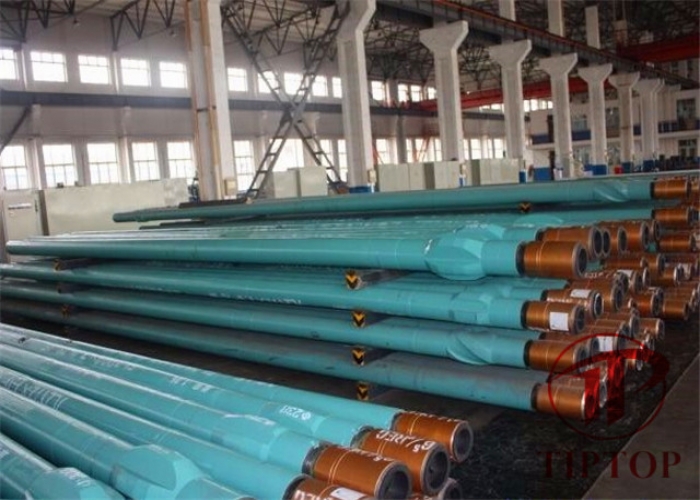

Pipe Ends Treatment: Overlay Welding, Seal Welding, Beveling.

Test and Inspection Items:

• Performance test: Mechanical, Chemical, Peeling Strength.

• Microscopic test: Microstructure, Hardness

• NDT-PT, UT, RT, Collapse test, Hydrostatic, CRA layer, PMI test.

• Integrity test: blasting test • Corrosion test: Intergranular corrosion, SSC, HIC, G28, G48.

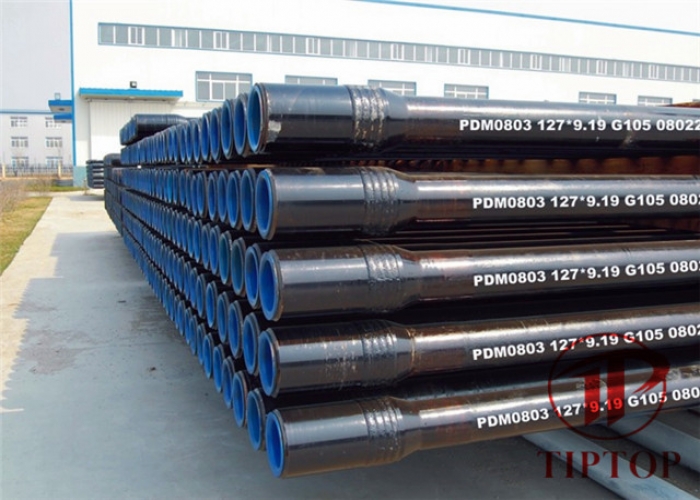

Finished Products Inspection: Chemical & Mechanical Inspection: Chemical component, stress & impulse test, intergranular corrosion test, metallography detection, stress corrosion, Simulated corrosion test and other 60 test items.

Core Inspecting Technology: Modal NDT Technology, Automatic UT Inspection System and Four-points Bending Test.

The sub sea CRA Clad Pipe can be widely used in oil fields, chemical industry, electric power, coal mine, municipal administration and other fields. Its scope of application is becoming wider and wider, and its economic, environmental and social benefits are more obvious.