C17200 BERYLLIUM COPPER ALLOY FOR DOWNHOLE DRILLING MOTOR & MWD MEASUREMENT WHILE DRILLING COMPONENTS

China Beryllium copper alloy is a non-ferrous alloy elastic material with excellent comprehensive performance, known as the "king of elasticity", Beryllium copper alloy has the excellent properties such has high strength, high hardness, corrosion resistance, high electrical conductivity, high thermal conductivity, fatigue resistance, corrosion resistance, less elastic lag, non magnetic, no spark during impact etc..

TIPTOP could offer available materials such as: QBE2,C17200 and C17510,C17500, By using materials Beryllium copper alloy,below products could be produced:

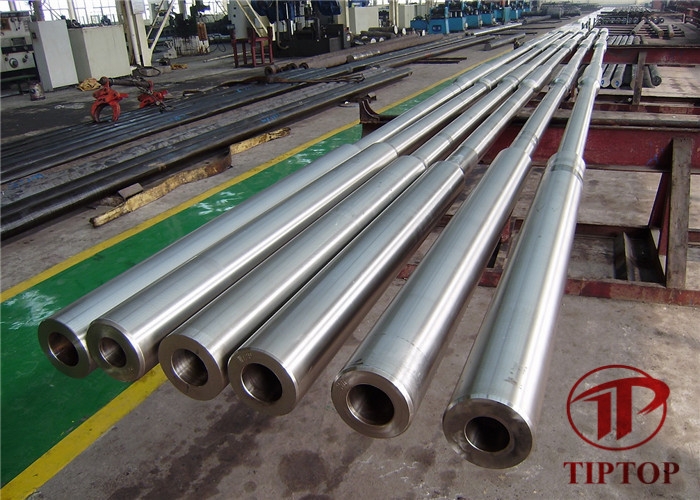

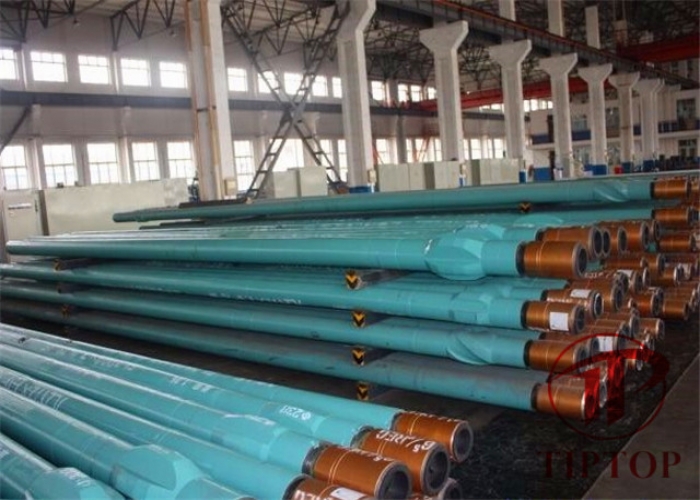

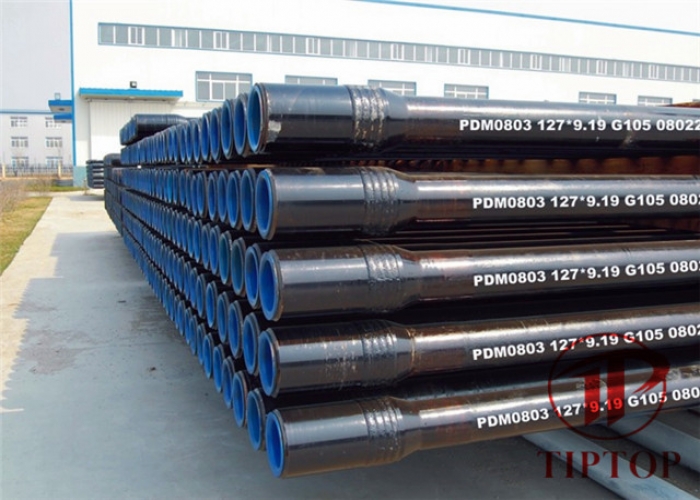

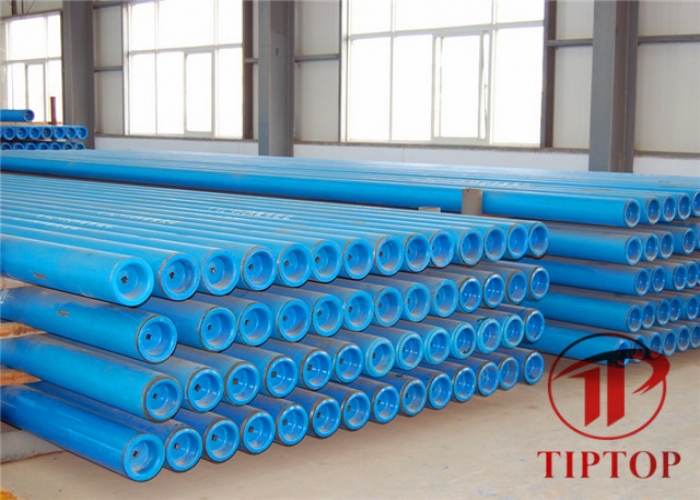

Threaded Saver subs, mud motor rotor & stator, Non-magnetic drill collars,MWD Measurement while drilling components, Interconnect Housing, Pressure Housing, Oil Fill Housing, Screen Housing Collar, Tube Collet, Top Shaft,Interconnect Shaft Interconnect Bushing, Bumper Sleeve,etc..

BeCU (UNS17200) tubes also called as C17200 Beryllium Copper Alloy tubes are widely used for non magnetic mud motor rotor & stators in the oil&gas,mining industry.TIPTOP produces drill string components with the beryllium copper materials, In the aged condition, beryllium copper has the same strenght as tempered alloys steels and can be substituted for steel and non-magnetic steel components in the drill string industry & mining industry, beryllium copper components are specifically manufactured to obain a unique combination of mechanical properties best suited or each components of the drill string.

Chemical Composition of BeCu(beryllium copper)Alloy |

Material Grade | Be | cobalt | Ni | Cobalt+Ni | Cobalt+Ni+Fe | Pb | Cu | Standard |

Qbe2 | 1.8-2.1 | - | 0.2-0.5 |

| ≤0.6 | ≤0.005 | Rem | GB/T5233-2001 |

C17200 | 1.8-2.0 | - | - | ≥0.2 | ≤0.6 | ≤0.02 | Rem | ASTM |

C17510 | 0.2-0.6 | - | 1.4-2.2 | - | - | - | Rem | ASTM |

C17500 | 0.4-0.7 | 2.4-2.7 | - | - | - | - | Rem | ASTM |

Mechanical Properties of BeCu(beryllium copper)Alloy |

Material Grade | Status | Heat treatment | Tensile strength

Kg/mm² | Yield strength

Kg/mm² | Elongation

(%) | HRC hardness | conductivity%

(IACS) |

QBe2&C17200 | A(TB00) |

| 42-60 | 14-25 | 20-60 | B45-85 | 15-19 |

H(TD04) | 59-92 | 52-74 | 8-30 | B88-103 | 15-19 |

AT(TF00) | 3hr 315-330°C | 116-141 | 91-123 | 3-10 | C36-42 | 22-28 |

HT(TH04) | 2-3hr 315-330°C | 123-159 | 91-141 | 1-9 | C36-45 | 22-28 |

C17510&C17500 | A(TB00) |

| 24-39 | 7-21 | 20-35 | B20-50 | 20-30 |

H(TD04) | 45-60 | 35-53 | 10-15 | B60-88 | 20-30 |

AT(TF00) | 3hr 480°C | 70-91 | 56-70 | 10-25 | B92-100 | 45-60 |

HT(TH04) | 2hr 480°C | 77-99 | 67-88 | 5-25 | B95-102 | 48-60 |