CHINA TIPTOP NON MANGNETIC STABILIZER FOR DIRECTIONAL DRILLING

The use of Non-magnetic stabilizer in oilfield:

1. Ensure casing centering.

During drilling Non-magnetic stabilizer can keep the casing centered in the wellbore. This helps improve cementing quality and enables cement slurry to be evenly distributed between the casing and the wellbore, enhancing the stability and sealing of the casing.

Avoiding casing eccentricity can reduce the risk of oil, gas, and water channeling after cementing due to possible local lack of cement slurry.

2. Reduce casing wear.

When the casing is not centered in the wellbore, it is easy to rub against the wellbore wall, leading to casing wear. Non-magnetic Stabilizer can reduce this friction and extend the service life of the casing.

Especially in complex geological conditions and deep and ultra-deep well drilling, the problem of casing wear is more prominent, and the role of Non-Magnetic Stabilizer is even more important.

3. Improve logging accuracy.

Non-magnetic Stabilizer are made of Non-magnetic materials and will not cause magnetic interference to logging instruments. This helps improve the accuracy of logging data and provides a reliable basis for geological analysis and oil and gas evaluation.

During magnetic logging, Non-Magnetic Stabilizer can ensure the stable position of logging instruments in the casing and reduce measurement errors.

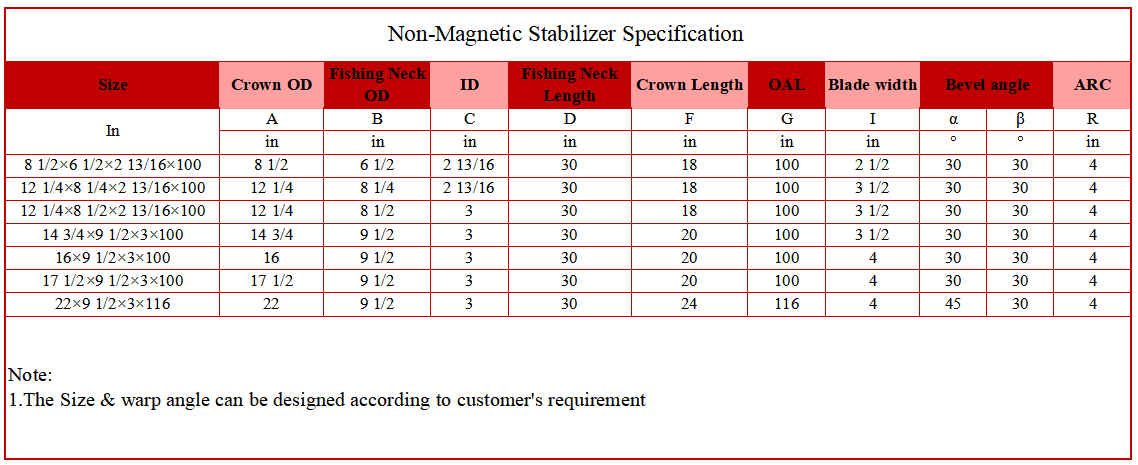

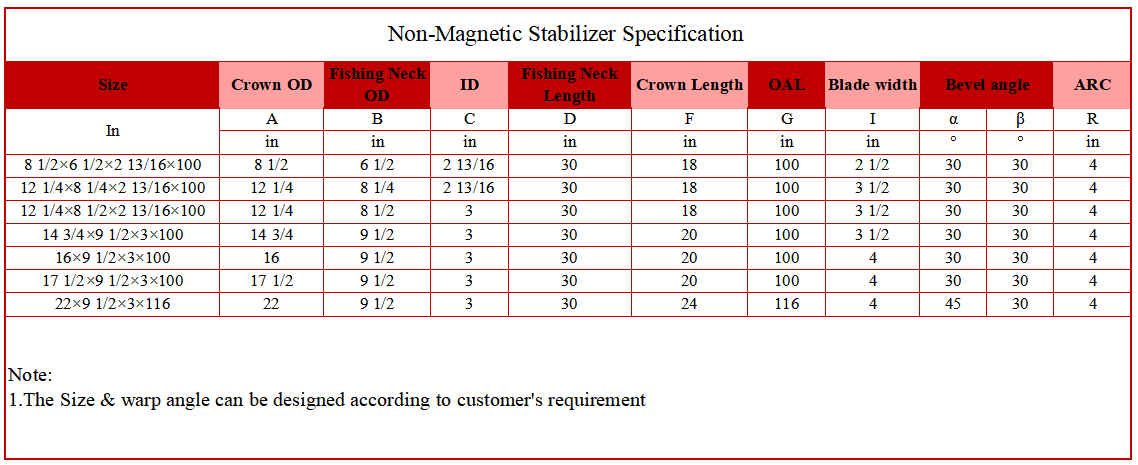

The specification of Non-Magnetic Stabilizer: