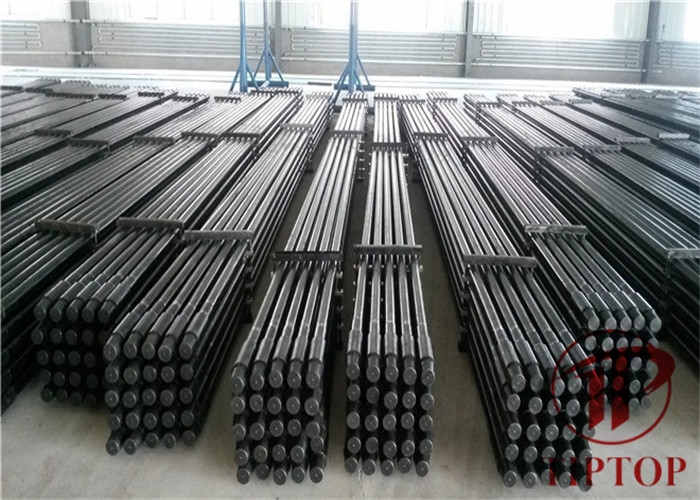

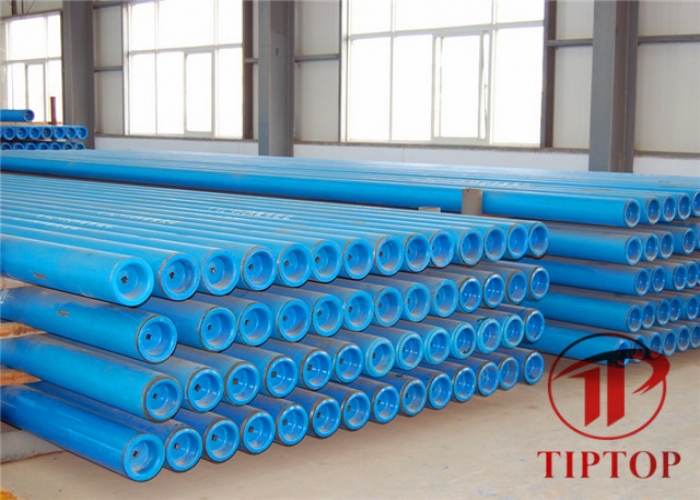

Drill pipe for Non-Excavating Horizontal Directional Drilling (HDD)

Non-Excavating HDD drill pipe is a steel pipe with threading at the end, which is used to connect the surface equipment of Non-Excavating drilling rig and the drilling and grinding equipment or bottom hole device at the bottom of the well. Non-Excavating HDD drill pipe is mainly used in horizontal directional drilling pipeline crossing and laying project, transporting drilling mud to the drill bit, and together with the drill bit, it becomes high, low or rotates the bottom hole device. Drill pipe needs to be able to withstand high internal and external pressure, twisting, bending and vibration. Drill pipe can be used multiple times during oil and gas extraction and refining.

Non-Excavating HDD Drill Pipe is divided into Non-Excavating Integral Drill Pipe and Non-Excavating Friction Welding Drill Pipe.

- Select special oil drilling pipe in line with API standards, with stable and reliable performance

- Unique double thickening technology of drill pipe joint

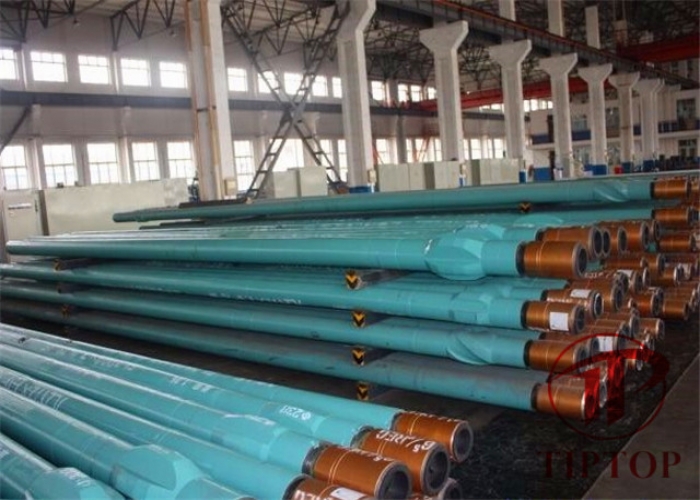

- The transition zone is smooth to reduce mud flow resistance

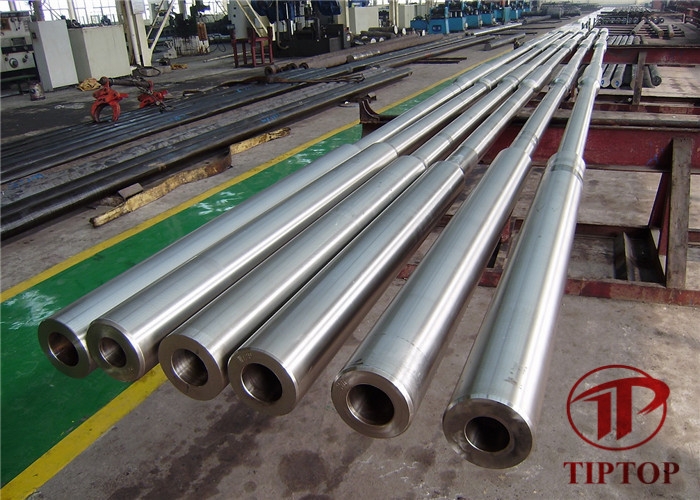

- China's first integral drill pipe intermediate frequency heat treatment line process technology

- The joint adopts high strength medium sandblasting technology and laser processing technology, hard layer 0.1-0.3mm

- The surface hardness, hard layer, uniform distribution of the two connecting ends, wear resistance, stability and reliability, improve the service life of drill pipe

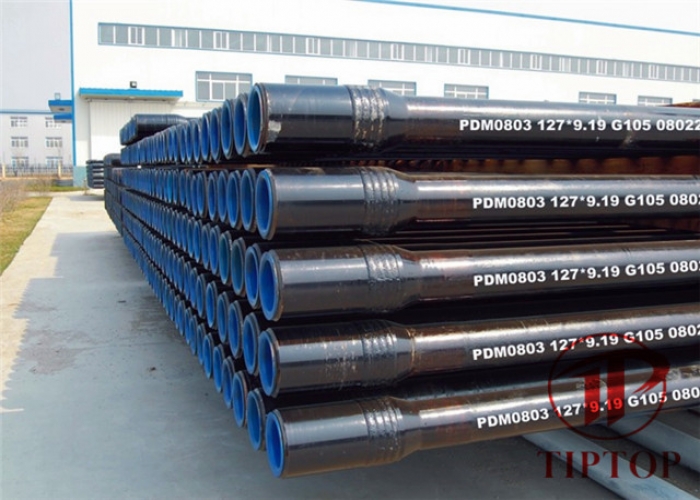

- Using special petroleum pipe, tube end thickening technology, tube end thickening in accordance with API 5D standard

- Hardening and tempering heat treatment of thickened tube body, steel grade can reach G105 or G135

- The joint blank is forged and pressed. The thread adopts laser heat treatment technology. The hard layer is 0.1-0.3mm, which conforms to API SPEC7-1 standard

- The welding area adopts deformation heat treatment technology and the welds meet API SPEC 7 standards

- Weld and joint are 100% flaw detection

- The weld shall be 100% tested under three-point pressure

The body of Non-Excavating HDD drill pipe we produce is made of special materials that meet the API standard, with stable performance. The thickening of the pipe section meets the API 5DP standard, the thickened pipe body is quenched and tempered, and the steel grade can reach G105 or S135. Modulation heat treatment after rough machining, surface desalination treatment after finishing machining, double shoulder high torsion joint thread adopts internal and external composite shoulder structure design, all adopt precision imported CNC lathes, the tightness of thread processing has been strictly guaranteed, there are higher tensile strength and torsional yield strength, all threads are equipped with thread gauges that meet international standards, so the quality of the drill pipes we produce is stable and reliable.