Cold drawn welded control line tube,

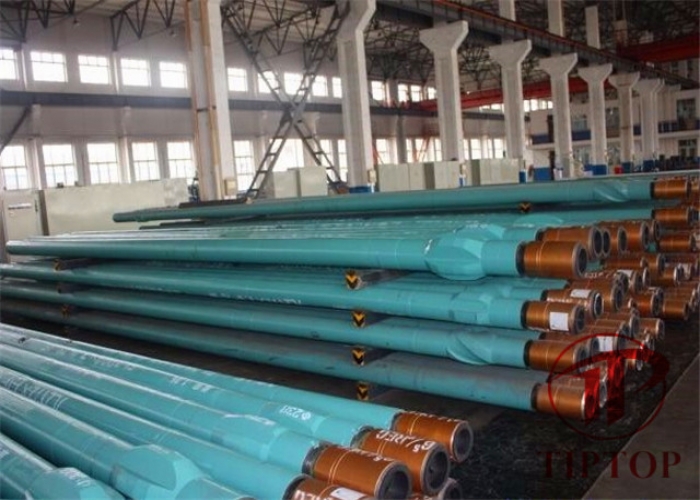

Coiled seam welded pressure tubing in the heat treated condition is typically used in oil and natural gas wells for applications including hydraulically actuated surface-controlled subsurface safety valves, chemical injection, and instrumentation. In such applications, it is commonly referred to as control line tubing.

The tubing is generally deployed by strapping it to the outside of the production casing. It may be encapsulated and can be included along with other pressure tubing or TEC and mechanical components, such as bumpers, within a flatpack. The tubing is frequently supplied as 5000 ft to 35000 ft. coils on a wooden or steel reel, depending on size.

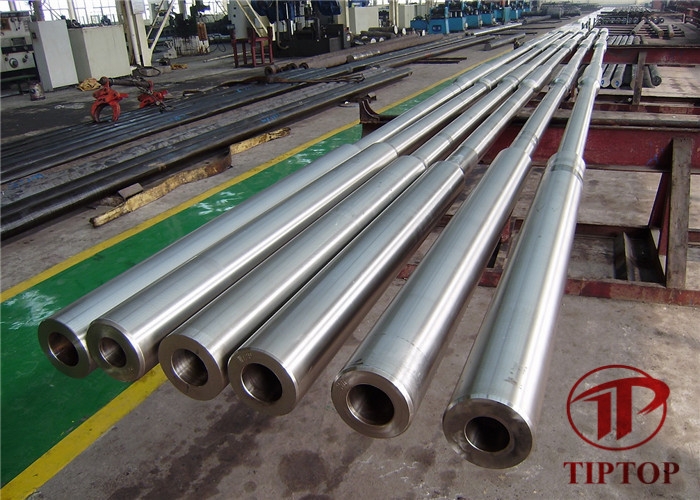

MANUFACTURING PROCESS AND RESULTANT PROPERTIES

The desired sizes are obtained by repeat cold drawing process, any welded joints are not

acceptable in each one coil ranging from 0.125 inch to 1 inch O.D. (3.2 mm to 25.4 mm) and a variety of wall thicknesses.

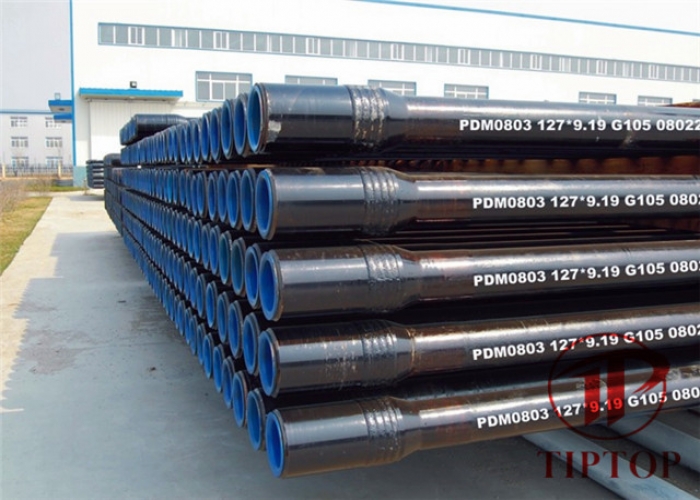

The strip is formed into a tubular cross section and longitudinally seam welded using either the gas tungsten arc (GTAW). The tubing may be welded at a larger outside diameter, sunk to final size and subsequently heat treated. Heat treated tubing is one continuous length of tubing, completely free of any welded joints or seams. Each coil is

100% hydrostatic tested.

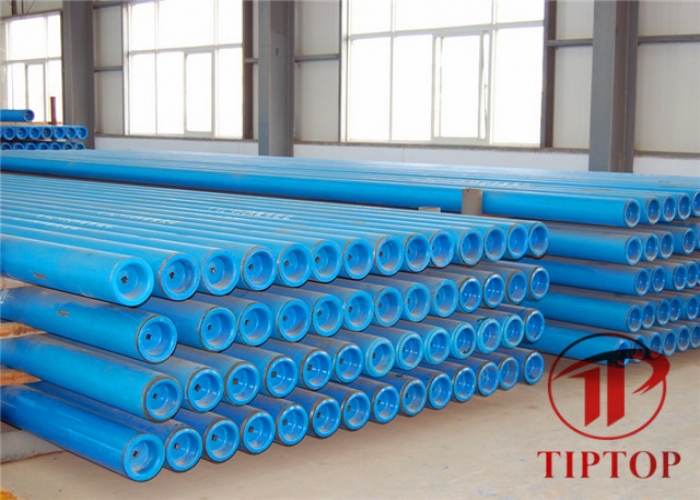

NONDESTRUCTIVE TESTING (NDT)

Eddy current testing (ECT) is performed on the longitudinally seam welded tubing. Radiographic testing and ECT are performed on material in the final heat treated condition. Yield pressure hydrostatic testing is performed on the heat treated tubing at final size.