Tiptop offers a variety of duplex stainless steel, super duplex stainless steel welded and seamless tubing, depending upon the properties the tubing is required to exhibit. Other alloys and sizes are also available upon request. Duplex stainless steels (named for their austenite and ferrite compositions), has greater yield strength than austenitic stainless steel.

Standard: ASTM-A 789 Standard specification for seamless and welded ferretic/austenitic stainless steel tubing for general service. This specification covers various grades of duplex stainless steels.

Chemical Composition

Grade | C | Mn | P | S | Si | Ni | Cr | Mo | N | Cu |

S31803 (2205) | 0.030 | 2.000 | 0.030 | 0.020 | 1.000 | 4.5-6.5 | 21.0-23.0 | 2.5-3.5 | 0.08-0.20 | … |

S322505 (2205) | 0.030 | 2.000 | 0.030 | 0.020 | 1.000 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 | 0.14-0.20 | … |

S32750 (2507) | 0.030 | 1.200 | 0.035 | 0.020 | 0.800 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 | 0.24-0.32 | 0.500 |

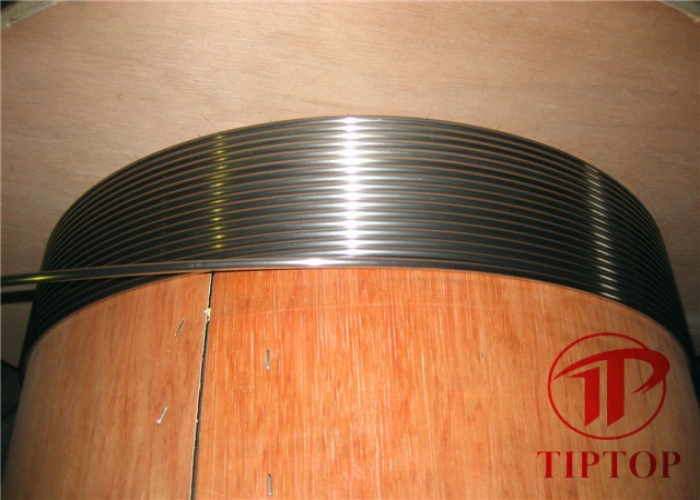

Duplex 2205 Stainless Steel Coiled Control Line Tubing Features

Close dimensional tolerances

Enhanced mechanical properties

Superior surface finish

High cleanness of inside surface

Controlled ovality, eccentricity

Delivery condition

Cold worked

Bright annealed

Annealed and polished

Application

Control line

Chemical injection line

Electrical line

Multi-line flat pack

Hydraulic line

Tubing encapsulated conductor

Intelligent well completions

Capillary tubing

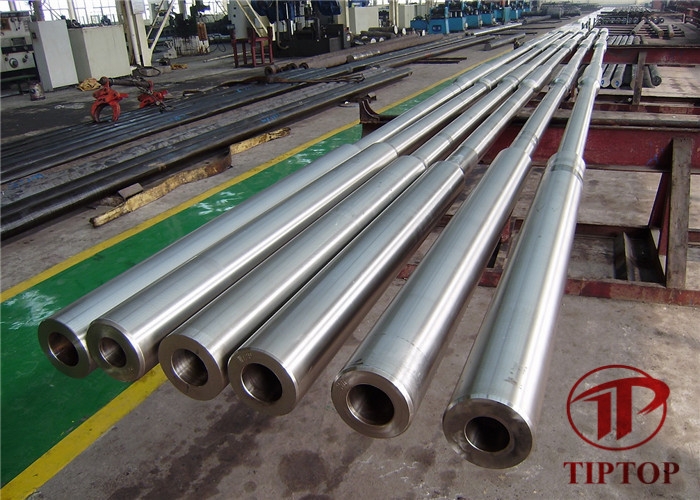

Seamless control lines are used in SCSSV, Chemical Injection, and Advanced Well Completions. Seamless tubes provide another tubing solution for our customer's complex well designs. The most common uses for Seamless line tend to be shorter length applications whereby no orbital welds are required.

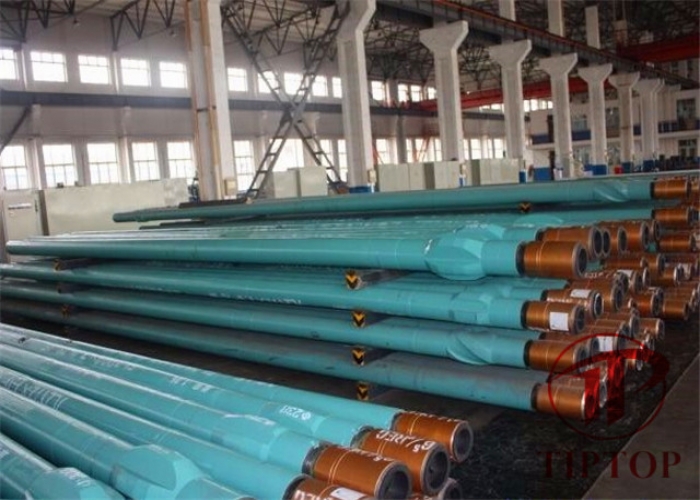

Welded Control Lines are the preferred construction for lines being used in downhole oil and gas applications. Our welded control lines are used in SCSSV, Chemical Injection, Advanced Well Completions, and Gauge Applications.