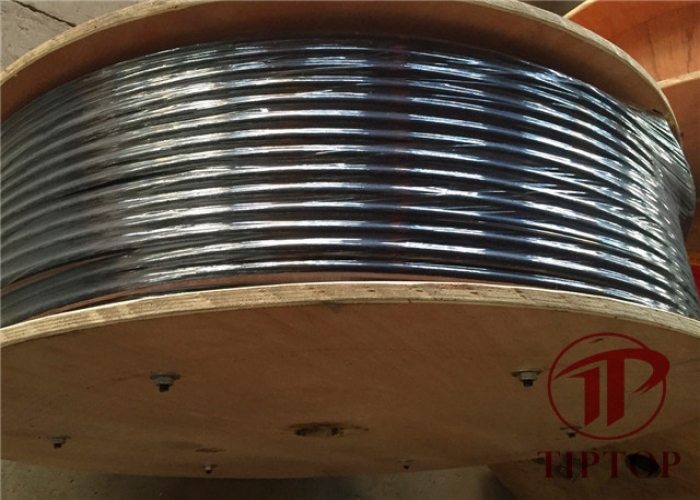

Encapsulated Tubing for Hydraulic Control Line and Chemical Injection Line

When you want to reduce the risk of leakage in your hydraulic line, and reach a high

resistance to corrosion at high temperature working environment, consider Tiptop

encapsulated control line.

High-Quality Polymeric Jackets Provide Added Protection

In answer to our customers’ individual needs, we have developed two primary jacketed

tubing. Your choice will depend on your process environment and your requirements. We

can help you arrive at the most cost-effective solution for your needs.

The core tubing is jacketed with the latest thermoplastic elastomeric compounds designed

to outlast the life of project tubing installations by reducing the possibility of corrosion and

mechanical damage. They can stand up to a wide range of chemical inhibitors and

seawater. The jackets are manufactured from fire retardant, all-weather,

abrasion-resistant compounds, designed to remain strong and flexible through wide

ranges of temperatures and pressures.

F46 Encapsulated Control Line

Encapsulation layer F46 is FEP, a co-polymer of tetrafluoroethylene and

hexafluoropropylene.

It is featured with:

■Keeping a stable performance at a working temperature from -85℃ to 200℃

■Resistance to a wide chemicals

■Resistance to creep

Nylon Encapsulated Tubing

The encapsulation layer Nylon is well-known as its resistance to wearing.

Features:

■Resistance to corrosion

■High breaking strength

■Good elongation at rupture

■High elastic recovery

■High durability to fatigue

Other encapsulation materials

are available:

■PVC

■PVDF

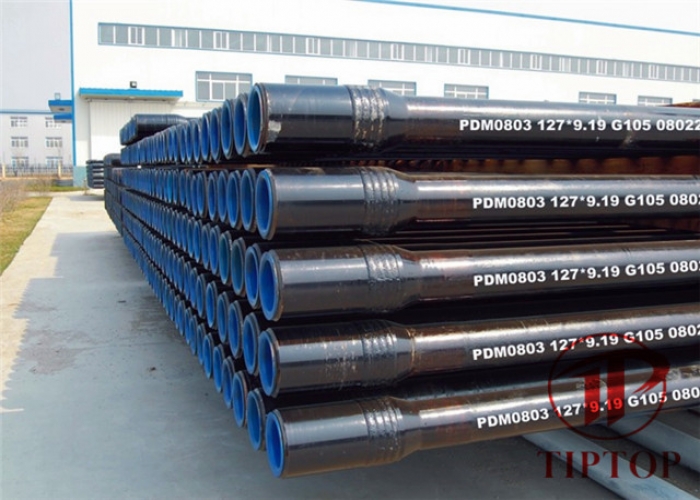

Material | OD (inch) | Wall Thickness (inch) | Working Pressure (MPa) | Length (M/Reel) |

316L, 304L, incoloy825, incoloy625, Duplex | 1/8” | 0.025”, 0.035”, 0.049” | 80--120 | 50--4000 |

316L, 304L, incoloy825, incoloy625, Duplex | 1/4” | 0.035”, 0.049”, 0.065” | 60--120 | 50--3000 |

316L, 304L, incoloy825, incoloy625, Duplex | 3/8” | 0.035”, 0.049”, 0.065” | 60--120 | 50--2500 |

316L, 304L, incoloy825, incoloy625, Duplex | 1/2” | 0.035”, 0.049”, 0.065” | 60--120 | 50--2000 |

Hydrostatic test for each coil and conform to ASTM standards and requested specifications.

The specification and length per coil can be customized according to customer’s requirements.