Oilfield Downhole Milling Tool Pilot Mill

Oilfield Downhole Milling Tool Pilot MillThe pilot mill is used to mill the fish which have inner bore instability and shake in the down well, such as drill pipe, drill collar, tubing etc. The pilot

Tel: + 86 05386368027

Oilfield Downhole Milling Tool Pilot MillThe pilot mill is used to mill the fish which have inner bore instability and shake in the down well, such as drill pipe, drill collar, tubing etc. The pilot

The pilot mill is used to mill the fish which have inner bore instability and shake in the down well, such as drill pipe, drill collar, tubing etc.

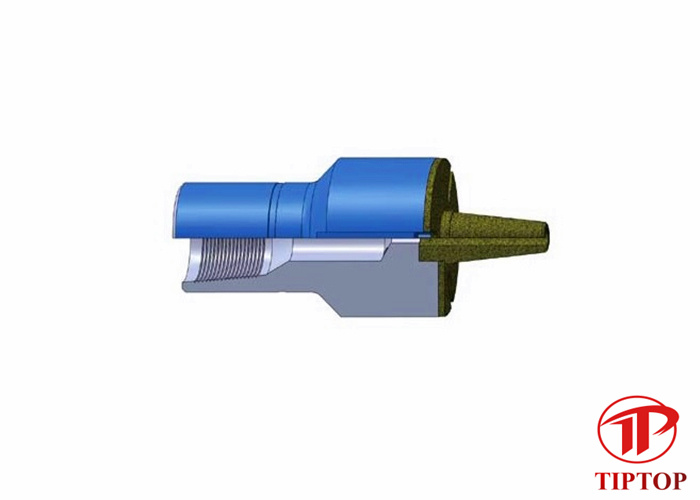

The pilot mill is made up of mill shoe body and pilot cone, as the following picture. The upper part of the mill shoe body is inner thread, the lower part is cylinder whose diameter is bigger. Welding YD alloy and anti-abrasive material on the back plane of pilot cone and mill shoe body. The pilot cone has the effect of leading and fixing the top of the fish. And there are 2-4 water crossing grooves on the back plane of the mill shoe body to make sure it can circulate unblocked.

The pilot mill shoes locate the fish by the cone which is entered into the fish, and then rotate with the drilling tool, the mill shoes welded with YD alloy grind the fish.

Pilot Mills have been proven in the field to be well suited for milling liner hangers, eliminating inside cuts. They are also well suited for milling washpipe, safety joints, crossover swages, and washover shoes. All sizes available according to customer specifications.

OD mm (inch) | Hole Size mm (inch) | Connection |

251 (9 7/8) | 273.0~295.3 (10 3/4~11 5/8) | 6 5/8REG |

215.9 (8 1/2) | 244.5~269.9 (9 5/8~10 5/8) | 4 1/2REG |

152 (5 63/64) | 168.0~187.3 (6 5/8~7 3/8) | 3 1/2REG |

143 (5 5/8) | 155.6~165.1 (6 1/8~6 1/2) | 2 7/8REG |

121 (4 3/4) | 130.0~139.7 (5 1/8~5 1/2) | 2 7/8REG |

98 (3 55/64) | 107.9~114.3 (4 1/4~4 1/2) | 2 3/8REG |