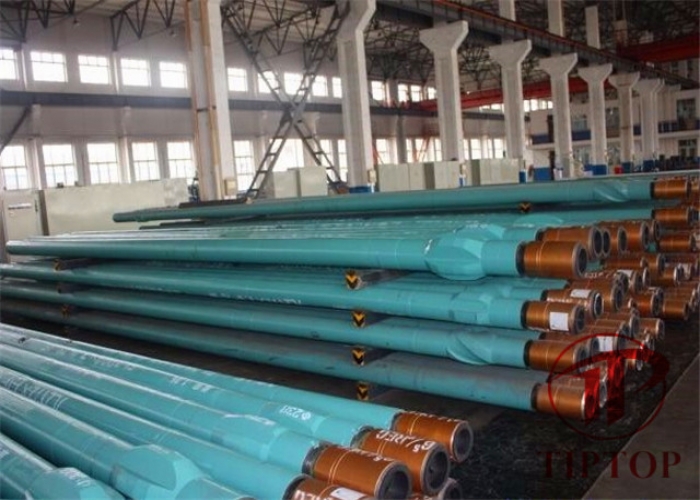

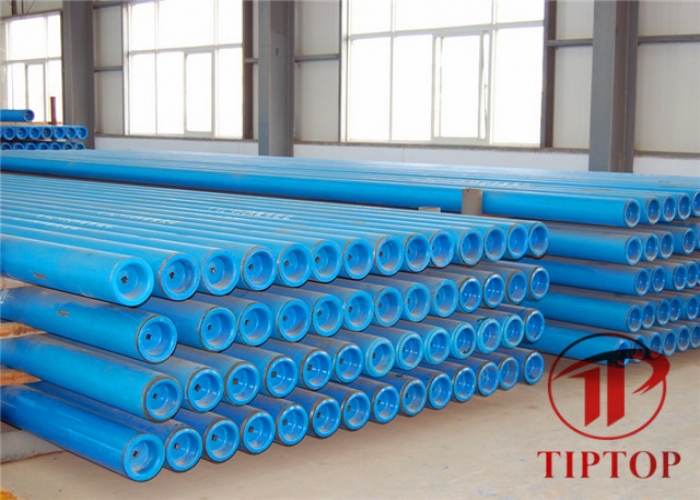

China NMDC Non Magnetic Drill Collars supplier

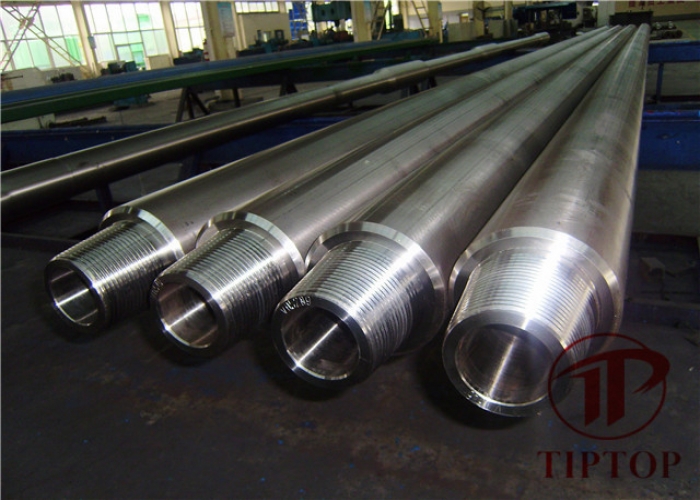

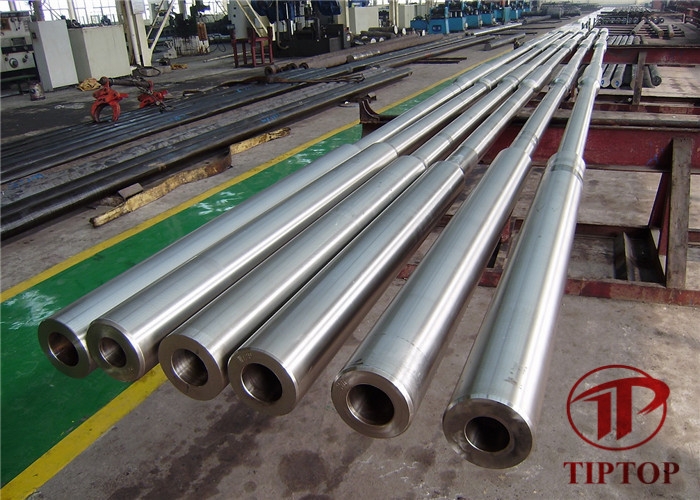

TIPTOP Non magnetic drill collars are made of a low carbon high-chromium manganese alloy steel. It is refined and forged after strict chemical composition control to achieve its mechanical properties, with good low magnetic permeability, high strength mechanical properties, excellent intergranular corrosion cracking resistance and wear resistance. When the magnetic field intensity is 1×105/4π A/m, the relative permeability of the non-magnetic drill collar is ≤1.010.

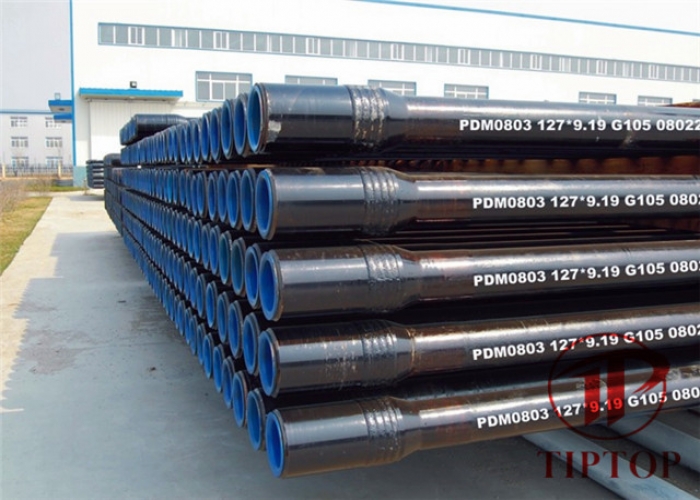

The API 7-1 Drill collars are available in lengths from 10 to 31 ft and outside diameter from 3-1/8" to 10". The nominal sizes and other relevant and important sizes are listed here.

Connection Type | OD | ID | Length

(ft) |

mm | in | mm | in |

NC23-31 | 79.4 | 3 1/8 | 31.8 | 1 1/2 | Available from 10 to 31 ft |

NC26-35(2 3/8 IF) | 88.9 | 3 1/2 | 38.1 | 1 1/2 |

NC31-41(2 7/8 IF) | 104.8 | 4 1/8 | 50.8 | 2 |

NC35-47 | 120.6 | 4 3/4 | 50.8 | 2 |

NC38-50(31/2IF) | 127 | 5 | 57.2 | 2 1/4 |

NC44-60 | 152.4 | 6 | 57.2 | 2 1/4 |

NC44-60 | 152.4 | 6 | 71.4 | 2 13/16 |

NC44-62 | 158.8 | 6 1/4 | 57.2 | 2 1/4 |

NC44-62(4IF) | 158.8 | 6 1/2 | 71.4 | 2 13/16 |

NC44-65(4IF) | 165.1 | 6 1/2 | 57.2 | 2 1/4 |

NC44-65(4IF) | 165.1 | 6 1/2 | 71.4 | 2 13/16 |

NC44-67(4IF) | 171.4 | 6 3/4 | 57.2 | 2 1/4 |

NC50-672(41/2IF) | 171.4 | 6 3/4 | 71.4 | 2 13/16 |

NC50-70(41/2IF) | 177.8 | 7 | 57.2 | 2 1/4 |

NC50-70(41/2IF) | 177.8 | 7 | 71.4 | 2 13/16 |

NC50-72(41/2IF) | 184.2 | 7 1/4 | 71.4 | 2 13/16 |

NC56-77 | 196.8 | 7 3/4 | 71.4 | 2 13/16 |

NC56-80 | 203.2 | 8 | 71.4 | 2 13/16 |

6 5/8 REG | 209.6 | 8 1/4 | 71.4 | 2 13/16 |

NC61-90 | 228.6 | 9 | 71.4 | 2 13/16 |

7 5/8 REG | 241.3 | 9 1/2 | 76.2 | 3 |

NC70-97 | 247.6 | 9 3/4 | 76.2 | 3 |

NC70-100 | 254 | 10 | 76.2 | 3 |

8 5/8 REG | 279.4 | 11 | 76.2 | 3 |

MECHANICAL PROPERTIES AS PER ASTM A370 |

|

Item | Tensile Strength (Mpa) | Yield Strength 0.2% (Mpa) | Elongation% | Charpy Impact Work(J) | Brinell Hardness

(HB) | Reduction Area(%) | IGC | Field Gradient

(μT) | Relative magnetic per meability |

Requested | ≥827 | ≥758 | ≥25 | ≥122 | ≥285 | ≥50 | / | ±0.05 | ≤1.010 |

Actual | 1135 | 1038 | 26 | 226 | 304 | 70 | Pass | Pass | 1.003 |